This home in Bowie, Maryland had a significant moisture

problem in the attic; in fact, on a cold winter day in January, the subroofing on the north side

of the house was covered in ice. To get rid of the moisture permanently, we'll be adding metal ridge vent at the

peak, and the Edge soffit ventilation at the eaves. This home in Bowie, Maryland had a significant moisture

problem in the attic; in fact, on a cold winter day in January, the subroofing on the north side

of the house was covered in ice. To get rid of the moisture permanently, we'll be adding metal ridge vent at the

peak, and the Edge soffit ventilation at the eaves. |

Metal

Ridge Vent Installation:

We will start by removing the ridge shingles and

eventually cutting a 2.5" slot in the 1/2" CDX plywood at the peak. We will start by removing the ridge shingles and

eventually cutting a 2.5" slot in the 1/2" CDX plywood at the peak.

|

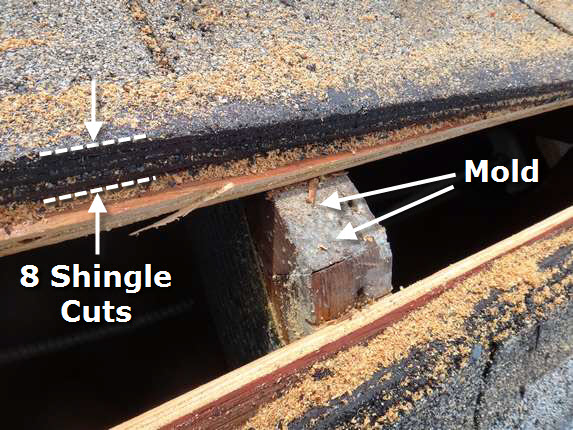

Since there are 2 layers of existing shingles on the roof,

we will be cutting through about 8 layers of shingles to get to the plywood. Since there are 2 layers of existing shingles on the roof,

we will be cutting through about 8 layers of shingles to get to the plywood. |

Why 8 layers, you ask? Well, there are two shingles per

layer that need to be cut, so technically, that's 4 shingle cuts per side -- however, the shingles

"lap over" to the other side at the peak. That's a LOT of cutting! Why 8 layers, you ask? Well, there are two shingles per

layer that need to be cut, so technically, that's 4 shingle cuts per side -- however, the shingles

"lap over" to the other side at the peak. That's a LOT of cutting! |

OK, we're down to the plywood. Time to cut the plywood. OK, we're down to the plywood. Time to cut the plywood. |

There is the evidence of the moisture ... the dreaded

mold. There is the evidence of the moisture ... the dreaded

mold. |

|

Now for the ridge vent area over the garage. Now for the ridge vent area over the garage. |

|

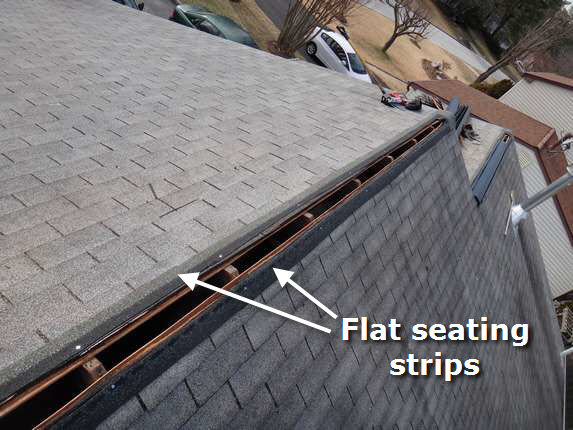

To get a flat seal between the metal ridge vent and the

shingle surface, we have carefully cut some strips from spare 25 year shingles and nailed them in

place. To get a flat seal between the metal ridge vent and the

shingle surface, we have carefully cut some strips from spare 25 year shingles and nailed them in

place. |

The new metal ridge vents by Air-vent Inc have been set into

Geocel sealant and screwed down with glavanized roofing screws. The new metal ridge vents by Air-vent Inc have been set into

Geocel sealant and screwed down with glavanized roofing screws. |

Note all of the fasteners holding down the vent. Note all of the fasteners holding down the vent. |

The ridge vent fasteners use steel and neoprene washers for

sealing. The ridge vent fasteners use steel and neoprene washers for

sealing. |

The Edge Soffit Vent

Installation:

Now it's time to prepare the eaves for the Edge Vent.

Once again, 2 layers of shingles are coming off; approximately 4 courses from the gutter. Now it's time to prepare the eaves for the Edge Vent.

Once again, 2 layers of shingles are coming off; approximately 4 courses from the gutter.

|

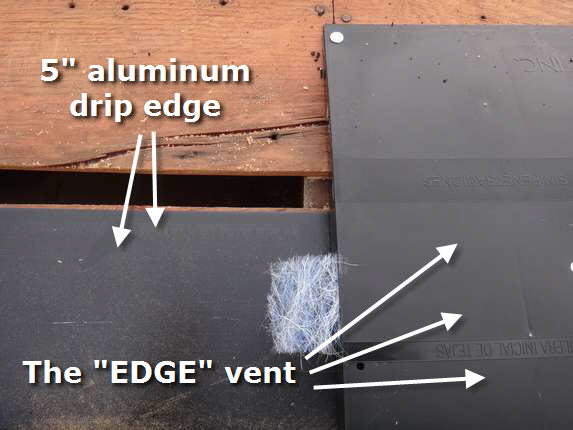

Next, our custom made 5" aluminum drip edge is installed

... Next, our custom made 5" aluminum drip edge is installed

... |

... then the required 1" slot is cut right above the protective

aluminum. ... then the required 1" slot is cut right above the protective

aluminum. |

AND the Edge Vents are nailed into place with 3" roofing

nails. Nice! AND the Edge Vents are nailed into place with 3" roofing

nails. Nice! |

Finally with all of the Edge Vents in place, all we need is

a covering of "ice and water shield" and

then some Certainteed XT25 three tab

shingles. Next up, a video showing a roof job we completed in Potomac, Md - with some more

detail about the ventilation we're using here ... Finally with all of the Edge Vents in place, all we need is

a covering of "ice and water shield" and

then some Certainteed XT25 three tab

shingles. Next up, a video showing a roof job we completed in Potomac, Md - with some more

detail about the ventilation we're using here ... |

|

|

Soffit Ventilation

(additional):

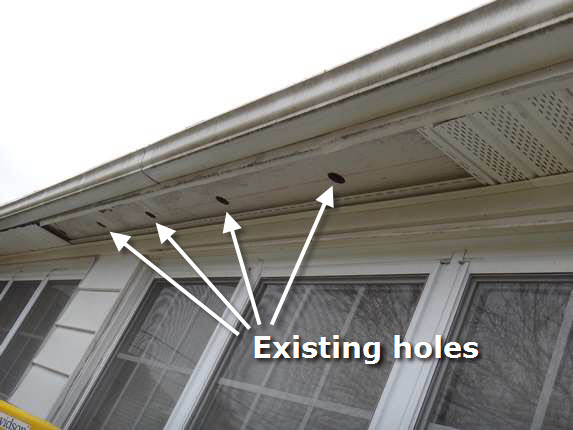

After installing the ridge

vent, we needed to check the existing soffit ventilation to see if there was enough (or any)

present. YES, some was there, but not nearly enough ... After installing the ridge

vent, we needed to check the existing soffit ventilation to see if there was enough (or any)

present. YES, some was there, but not nearly enough ...

|

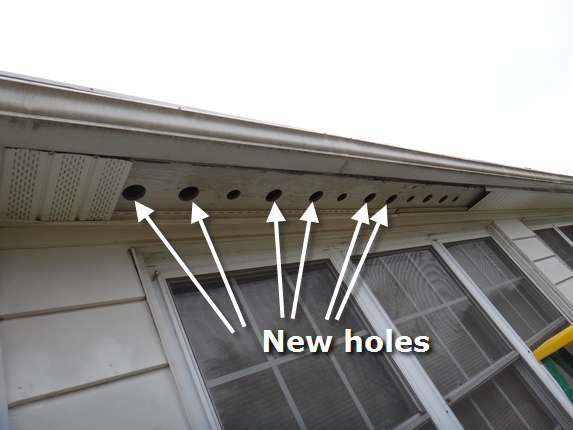

...so after performing some calculations, we figured out the

required amount of new soffit ventilation needed, and

installed the correction (above and below pics). ...so after performing some calculations, we figured out the

required amount of new soffit ventilation needed, and

installed the correction (above and below pics). |

|

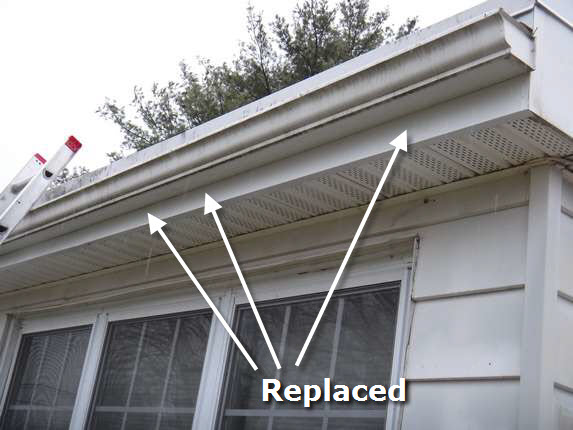

After all the lanced soffit panels were re-installed, we

custom formed a new section of white aluminum fascia to replace the old. Done! After all the lanced soffit panels were re-installed, we

custom formed a new section of white aluminum fascia to replace the old. Done! |

And finally, we corrected the last two leaky areas on the

roof; 1. heater exhaust base, and 2. pipe collar on fan vent. And finally, we corrected the last two leaky areas on the

roof; 1. heater exhaust base, and 2. pipe collar on fan vent. |

The roofing here wasn't installed very well ... The roofing here wasn't installed very well ... |

...so we removed the old shingles around the unit. ...so we removed the old shingles around the unit. |

Then, we installed new Certainteed XT25 shingles,and sealed

underneath with Geocel Tripolymer Sealant. Then, we installed new Certainteed XT25 shingles,and sealed

underneath with Geocel Tripolymer Sealant. |

OK, this leak is fixed! OK, this leak is fixed! |

The pipe collar, installed by others, was done

incorrectly. The pipe collar, installed by others, was done

incorrectly. |

OK, now we're in good shape! OK, now we're in good shape! |